Consistent results!

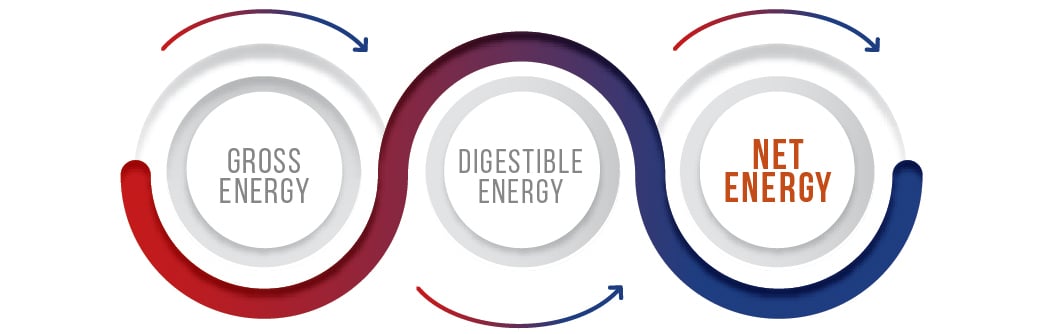

Our continued commitment to tailoring nutrition and health programmes allows fish farmers to achieve a better feed efficiency. That’s why we introduce the NET ENERGY concept.

All animal feeds contain a certain amount of energy, which is mainly derived from protein, fat and carbohydrates. This dietary energy has been used as a predictor for growth in feed formulation for years, but when a feed is eaten by the fish, some of this energy is not digested and therefore not available to the fish. Of this digestible energy, again a part is lost as the result of metabolism. The energy which is available in the end for maintenance and growth of the fish is called net energy.

Even though the digestible energy can be calculated relatively simply if the digestibility of the various feed ingredients are known, not all forms of this digestible energy (from protein, fat and carbohydrates) are being utilised with the same efficiency. The use of a net energy evaluation system, where the different proportions of energy are taken into account, should therefore increase the accuracy with which feed can be formulated, especially in times where fishmeal is getting limited and the proportion of plant protein sources is still increasing in commercial feeds.

ONE STEP FURTHER!

All animals require protein and energy to grow and are therefore the main focus in animal feed evaluation. In the past, this has been done by looking at the crude nutrients in feeds (protein, fat and carbohydrates), but over the years the focus has more shifted at looking into the part which is actually available to the animal. Because when a feed is eaten by an animal, some of the protein and energy is not digested and therefore not available to the fish. Of the digestible part, again a part is lost as the result of metabolism. The energy which is available in the end for maintenance and growth of the fish is called net energy and it is the evaluation of this net energy in aquafeeds where Alltech Coppens will focus on the coming years.

The use of net energy in feed evaluation is not a new concept in animal nutrition and has been already considered standard industry practice in pig feed evaluation for decades. However, feed evaluation in aquaculture is at the moment still commonly based on digestible energy levels and is therefore running behind in comparison with pig nutrition.

Alltech Coppens has already started to implement this net energy approach in feed evaluation for some trout feeds where the utilisation efficiency of the different macronutrients are accounted for as well. Implications of the use of this net energy approach are that the crude analytical values of these products can deviate slightly between batches while keeping the same level of net energy, leading to constant performance. We believe that with the use of this net energy approach we can make the next step in aquafeed evaluation.

Q: Why formulate on net energy instead of digestible energy?

A: Most feed companies formulate on a fixed digestible energy level which already takes away part of the variation in digestibility of raw materials when fish feeds are formulated in a flexible way. However, research has shown that not all forms of this digestible energy (either from protein, fat or carbohydrates) are utilised for growth with the same efficiency. Fat is for example used for growth with a higher efficiency then carbohydrates. By formulating on net energy we go one step further and also take into account these differences in the utilisation of the different forms of energy.

Q: Is my fish is going to be effected by this (will they for example eat less)

A: There is always a certain time that fish need to be adapted on a new batch of feed, for feed formulated on a net energy level this will not be different. The first thing we take into account when formulating feed is that the feed needs to be highly palatable. When palatability is assured the maximum feed intake is for a big part related to the energy content of the feed. Because we formulate on a constant net energy value this will also mean that it will enable a constant high feed intake.

Q: What does it help me as a farmer?

A: By implementing this concept we can take into account differences in the quality of raw materials throughout the year and therefore assure a constant feed quality. Normally the cost price of feed is dependent on the price of the raw materials. With this concept we are less dependent on the price of raw materials and will make sure feed prices will not unnecessarily increase.

Q: Why not implement this in different feeds?

A: In feeds for recirculating aquaculture systems (RAS) we know that a constant feed recipe will lead to a better performance because of the fact that you are not only feeding the fish but also the biofilters in the system. Implementing this concept will therefore be done in feeds for non RAS or semi RAS systems and will be implemented in more feeds over time.

Q: Will the quality of the feed change?

A: Although the crude analysis (f.e. protein and fat) might differ slightly between batches of feed the net energy on which the feed is formulated will stay the same between batches. This will ensure a constant performance between batches of feed.

Q: Will this affect the water quality?

A: Although the net energy value of the feed will stay the same, it can occur that the digestibility of the macronutrients can differ slightly between batches. However, all raw materials used by Alltech Coppens have been intensively screened at the Alltech Coppens Aqua Centre. Raw material with the highest digestibility are selected, leading to the lowest pollution. Additionally, we not only formulate on a fixed net energy value, we also formulate on a fixed digestible protein to net energy ratio which will make sure the protein utilization will stay the same between batches.